Adhesive Peel Tester supermarket|180° peel testing : trading ASTM D903 is a standard test procedure developed in accordance with international standards to determine the comparative peel or stripping characteristics of adhesive bonds. ASTM D903 . Resultado da The latest tweets from @sakimichana

{plog:ftitle_list}

Resultado da xHamster Creators. Veja a Pamela Santos, também conhecida como Pamella Santos, pelada fodendo com força em vídeos pornos de sexo .

A peel adhesion tester is a specialized instrument designed to measure the adhesive strength of materials, including tapes, labels, films, and other packaging components. It simulates real-world scenarios by applying a .ASTM D3330 Test Methods. ASTM D3330 includes six distinct test methods (A-F) to evaluate different types of peel adhesion. Here’s an overview: Method A – Measures 180° peel .

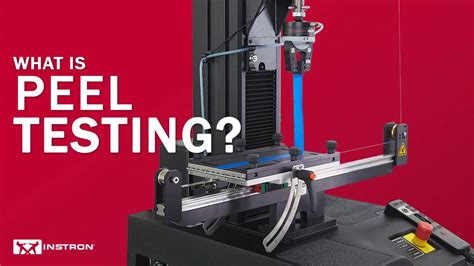

Peel testing is critical for evaluating the seal strength of various adhesive bonds. Some bonds, such as those that seal consumer packaging, are intended to be break at low forces, while others, such as those used in automotive .ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to as the “T-Peel” test because the sample looks like the letter “T” when loaded .ASTM D903 is a standard test procedure developed in accordance with international standards to determine the comparative peel or stripping characteristics of adhesive bonds. ASTM D903 .How to Perform an Adhesive Strength T-Peel Test – ASTM D1876. There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, .

what is peel testing

testing adhesive strength

ASTM D3330 is a major peel testing standard that outlines the requirements for determining the peel adhesion properties of pressure-sensitive tapes such as surgical, electrical, packing, and duct tape.

Testing the peel strength of bonded materials is one way to evaluate their adhesiveness. The peel strength is determined by applying a constant shear stress to the materials and calculating the resulting force multiplied by the .ASTM D903 Adhesives Peel Strength Testing. ASTM D903 is a common test performed for determining the strength of adhesive bonds. In the following procedures, a piece of tape or adhesive is bonded to a standard material and .

peel testing system

ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing standards such as ASTM D1781, ASTM . 180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle.The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.An adhesion tester measures the force required to detach a coating from a substrate. Often called a pull-off adhesion tester or peel tester, an adhesion tester applies a large amount of force to evaluate a coating's bond strength. When measuring peel force or adhesiveness, the nature of the substrate's surface plays a significant role. However .

peel testing methods

Testing Equipment for Peel Adhesion. A multi-functional peel tester is used to evaluate the peel force in different peel angles, rates, and temperatures (Figure 1). The peel tester is capable of evaluating independent parameters of peel rate from 15-300 cm/min, angle from 0° to 180°, and temperature (by aA peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).ASTM D3330-- Standard Test Method for Peel Adhesion of Pressure Sensitive Tape ; ASTM D3654-- Standard Test Methods for Shear Adhesion of Pressure Sensitive Tapes ; ASTM D904 -- Standard Test Method fo rComparison of Bond Strength or Ply Adhesion of Similar Laminates Made from Flexible Materials ;ASTM D903 | Adhesives | Peel Testing. ASTM D903 is a common test performed for determining the strength of adhesive bonds. In the following procedures, a piece of tape or adhesive is bonded to a standard material and peeled backwards at a 180 degree angle. The main calculation determined through this ASTM standard is average peel or stripping .

Benefits of Peel/Seal/Bond and Adhesion Strength Tester. The Presto Adhesion Strength Tester serves the purpose of measuring the enduring adhesion or peelability of self-adhesive pressure-sensitive materials. Peel adhesion, in this context, refers to the force needed to remove a pressure-sensitive coated material from a standard test plate under specified conditions, at .ChemInstruments offers a wide range of adhesive and release testers including the AR-1000, Peel Adhesive Testing Machines, Release Machines and Unwind Machines for use in adhesive testing laboratories.The ADMET eXpert 7601 adhesive and peel testing system has been designed to allow users to perform a wide variety of adhesive tests on a single easy to use and compact instrument. You can confidently report results knowing that the system has been engineered to meet all accuracy requirements specified in major standards organizations including .

Peel testing of adhesive and pressure sensitive tapes is used for quality assurance, and provides a means of assessing uniformity of the adhesion of a given type of tape. The assessment may be within a roll of tape, between rolls, or between production lots. Adhesive properties for tapes are measured using a standard test surface, a specified angle and test . A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel Adhesion-Face Stock test method. In addition, as the need to compare test results from other parts of the world increases, it is important to be .

peel testing machine

(a,b) The intra-test CV trends changed to a decreasing trend after peel rate of 0.707 mm/sec for both PTFE and PEEK demonstrating that the asynchronous failures of filaments of adhesive layer is .

water vapor permeability test procedure trading

PSTC-101 is a standard test method to measure peel adhesion strength in pressure s. FTM-9 Pressure Sensitive Tape Loop Tack Test Equipment. Loop tack tests provide the means of assessing the most important and yet the hard. ASTM D903 180 degree Peel Strip Strength of Adhesive Bonds. ASTM D903 is a standard test procedure to determine the .Test Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .

Test angle is permanently set for 180° testing; 10 pound load cell is included with the machine; Capable of pulling up to 10 lbs (4.5 kg) Test samples as short as 1/2” to as long as 6” (12-150 mm) Designed to accept standard 2” x 6” peel .

water vapor permeability testing equipment trading

which time the force required to effect peel is measured. 4.2 Test Method B—Adhesion to Backing, Single-Coated Tapes—A strip of the tape under test is applied to a rigid panel. A strip of the tape under test is applied to the backing of the first strip of tape and tested for peel adhesion as described in Test Method A.ASTM D903 is a standard test procedure developed in accordance with international standards to determine the comparative peel or stripping characteristics of adhesive bonds. ASTM D903 provides guidance on testing standard-sized specimens at precisely controlled test machine speed. Our engineers are familiar with the ASTM D903 test procedure and can guide you .Professional Automatic Peel Tester for Adhesives - Precision Peel Adhesion Test for Research & Quality Management - Your Number 1 Partner. Real values for our customers & clients. USA: +1 720 897 7818 UK: +44 161 408 5668 AU: +61 2 8091 0618 Email: [email protected] QUALTECH PRODUCTS .

PSTC-3 Peel Adhesion of Double Coated Pressure-Sensitive Tapes at 180° Angle PSTC-4 Adhesion to Liner of Presure-Sensitive Tapes at 180° Angle 3. Terminology 3.1 Definitions—Terminology found in Terminology D 996 shall apply. 4. Summary of Test Method 4.1 Test Method A—Single-Coated Tapes, Peel Adhesion at

Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.Adhesive peel tester Product Introduction: Adhesive peel tester is an multifunctional tester, a ccurate and effective peel tester testing with 90 ° and 180 ° tape peeling, peel tester be with s ervo motor drive, precision ball screw drive, the computer set the test speed directly for adhesive force the physical property of strength resistance.Peel adhesion can also be extended to apply to thermal bonds or other types of mating between materials. Because substrate cleanliness is so important to gathering reliable data, appropriate measures must be taken to ensure freedom from dirt, grease, and other contaminants. Below are a few of the standards that employ peel testing: ASTM D903 .Adhesion testing after the coating process will quantify the strength of the bond between substrate and coating, or between different coating layers or the cohesive strength of some substrates. Routine adhesion tests are used as part of inspection and maintenance procedures to help detect potential coating failures.

STANDARD PEEL ADHESION TESTS. Standard peel adhesion tests allow you to quantify the relative peel resistance of adhesive bonds in a repeatable manner, which benefits many areas of manufacturing. One industry standardized test for these measurements is ASTM D1876: Standard Test Method for Peel Resistance of Adhesives (T-Peel Test). However .Work with us to find the right equipment for your ASTM standard ASTM D3330 | Adhesives | Peel Testing Pressure sensitive tape is used in a variety of applications including duct tape, electrical tape, masking tape, packaging, double-sided tape, bandages, medical devices, and other uses. ASTM D3330 includes six different methods for testing the

water+vapor+permeability+tester trading

single yarn strength tester trading

WEBOi Fibra Porto Alegre: Confira as melhores ofertas da Oi Fibra Porto Alegre e escolha o seu pacote de internet. 🚀 Aproveite os planos de Internet Oi fibra! 400 Mega por apenas .

Adhesive Peel Tester supermarket|180° peel testing